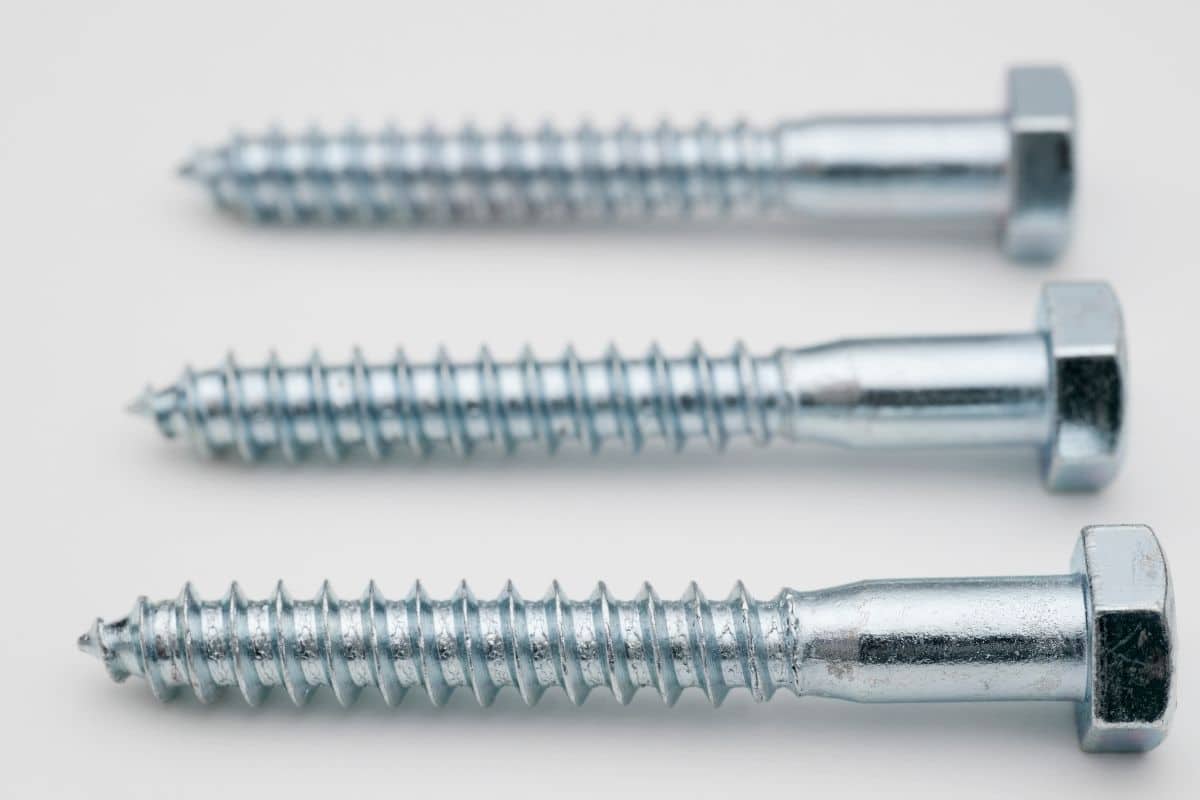

Socket Screws are a common type of fastener used in a variety of applications. These screws have a built-in hexagonal internal drive, and they require a special type of wrench to be loosened or tightened.

These screws may be rolled, cut, or ground threads depending on the manufacturer and application. They may also be heat treated to increase strength and durability.

1. Strength

Socket head cap screws are a type of screw with a built-in hexagonal internal drive that requires a special wrench to install. They are typically used in applications where space is limited and there is a need for high-strength fasteners.

They are graded by strength, indicated by two numbers separated by a point. The first number represents the ultimate tensile strength (UTS) of the screw, while the second number indicates the ratio of the yield strength to the UTS.

The higher the UTS, the stronger the screw. At Patriot Bolt and Fastener, we adapt to diverse industrial needs by incorporating specialty materials into our manufacturing process to produce high-strength socket head capscrews. These specialized materials ensure the best possible performance for your specific environment and application. This includes meeting industry standards and ensuring consistency in both strength and dimensions. This ensures that your screws will be compatible with various components and can withstand high levels of stress.

2. Aesthetics

Socket screws are used in a variety of heavy-duty and structural applications. They are also a popular choice for projects that require a low-profile design or access to tight spaces.

A hex socket cap screw, sometimes known as a dome head socket screw or Allen socket screw, has a wide load-bearing surface and offers an attractive finished look to the application. They provide more torque than standard hex screw varieties, making them ideal for lighter assemblies with low side-clearance restrictions.

Hex socket screws are available in a variety of thread sizes and materials to suit a wide range of mechanical projects. Their durability and aesthetics make them a popular choice for a variety of industrial processes including steel fabrication, furniture manufacture and automotive production lines. Rigid process controls on the manufacturing floor ensure that hex socket screws meet the highest industry standards in terms of fit, form and function. Tooling and dies are carefully monitored to prevent fatigue and wear and the heat treating process is closely managed to ensure consistent corner angles and dimensions in the thread profile.

3. Flexibility

Depending on the specific application and environment, socket screws are available in a variety of head styles, diameters and materials. This flexibility allows them to adapt to diverse industrial needs and environments.

Like all screw types, socket caps are subject to a certain amount of stress that is determined by tightening torque. Too little and the fastener remains loose; too much and it can damage or break. In order to avoid over-tightening, a good rule of thumb is to follow the manufacturer’s recommended specs for your particular project.

For example, Holo-Krome inch slide and metric socket set screw charts include torque figures for flat, low, button, and socket cap heads. These specifications, also called hex torque values, are an easy way to reference proper torque when working with these high-strength fasteners. They are particularly useful for heavy-duty applications, as they typically have a higher tensile and yield strength than other screw types and fasteners. This makes them suitable for more demanding applications where a secure connection is key.

4. Accessibility

Socket Screw is a fastener type that has a cylindrical head with a hexagonal socket (also known as an Allen socket) in the center. Its design gives it a sleek and low-profile appearance. This makes it popular in applications where aesthetics and a smooth shaft are important. It is also ideal for tight spaces.

The hex drive built into the socket allows it to be tightened and loosened using an Allen wrench or hex key. This distinguishes it from other screw head drive styles such as Phillips, slotted, and flathead screws, which require a screwdriver.

Hex drive socket screws also provide better grip than other types of screws, even when subjected to vibration. This helps them resist loosening, which is a common problem with other fasteners. They also offer superior clamping force, allowing you to use fewer socket screws than you would with other types of fasteners. This makes them a smart choice for assembly and manufacturing applications where space is limited.