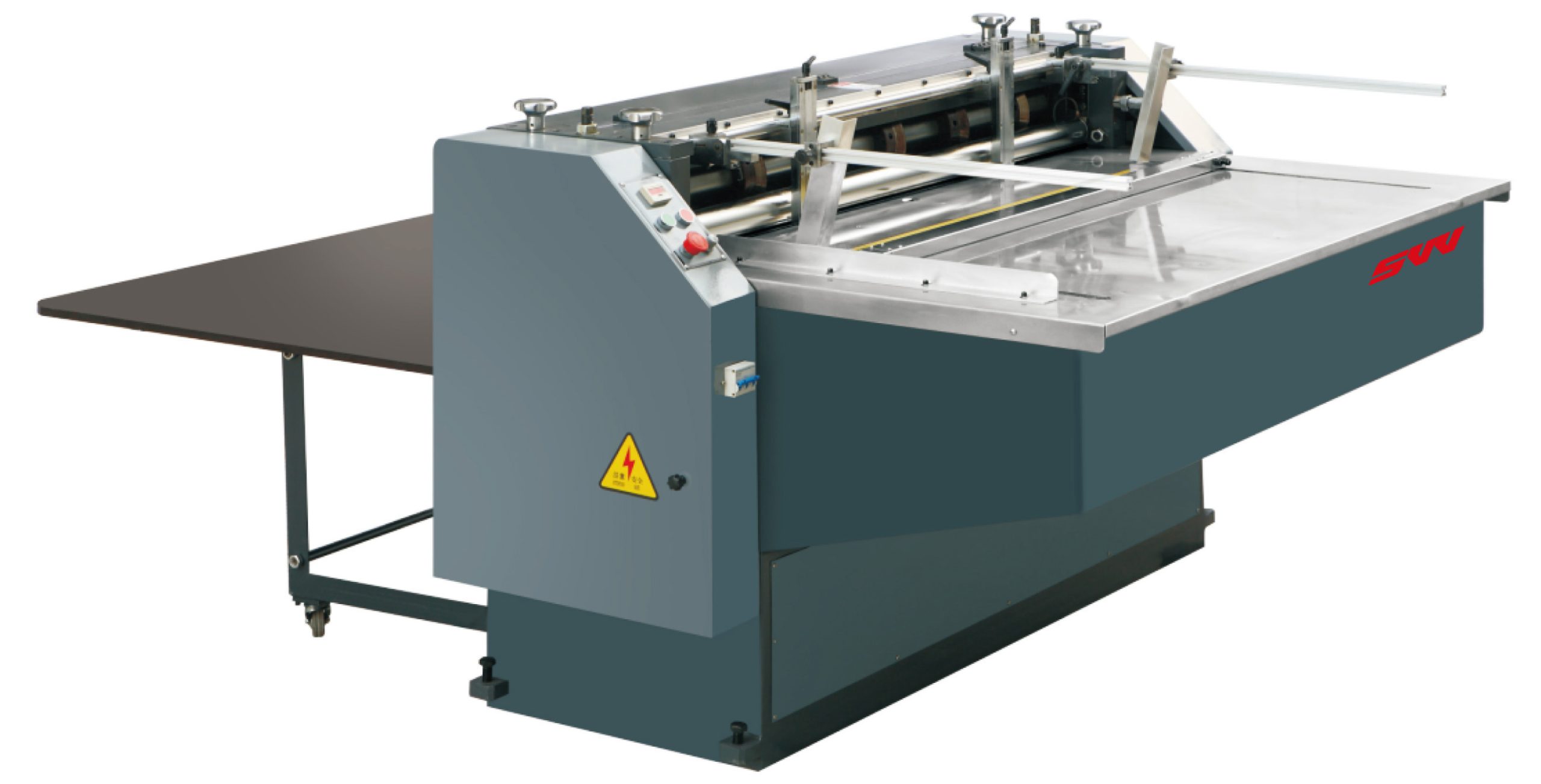

A hydraulic cutting machine is a powerful tool for cutting a variety of materials. It is used in many different industries. It is important to choose a good manufacturer and understand how to operate this machine safely.

The machine uses electricity to control solenoid valves, cylinders and oil pressure, based on operating instructions. It also uses a central automatic lubrication system to reduce wear and tear.

Factors to Consider When Selecting a Manufacturer

Hydraulic cutting machines are a powerful tool for the manufacturing industry. They can cut and shape a variety of materials, including foam and textiles, with speed and precision. They are widely used in various industries, from automotive to construction to household goods.

To choose the best hydraulic cutter for your needs, consider the following factors. You should look for a machine that has appropriate safety features and is easy to operate. It should also be economical and offer a good return on investment.

You should also consider the type of hydraulic fluid that your machine requires. A quality hydraulic fluid is essential for the machine to run properly. It must be free from contaminants, as it may cause damage to the machine and pose health risks for the operators. You should also pay attention to the price of the hydraulic cutting machine, as it can vary widely depending on the manufacturer. The cost may include a range of additional costs, such as maintenance and repairs.

Safety Measures

It is important to take safety measures when using a hydraulic cutting machine. This includes proper lubrication and conducting regular safety inspections to prevent accidents. It is also important to understand how the machine works, as this will help you make more informed decisions about its use.

Itãs important to note that hydraulic cutting machines are powered by high-pressure hydraulic fluid. This means that any leaks or spills can be dangerous to workers and cause significant damage to equipment. This can lead to unscheduled downtime and costly repairs.

In addition, itãs important to follow the machineãs instructions for operation. For instance, it is not allowed to cut explosive articles, bars, or thin workpieces. Also, the clutch should be disengaged and the motor should not start with a load. Lastly, itãs important to keep hands and feet away from the blades of the shearing machine. This will prevent them from being stabbed or injured by the machine.

Maintenance

A hydraulic cutting machine is a type of machinery used in factories to cut materials. It uses a hydraulic system to power the cutting blade, which allows for efficient and precise cuts. The machine can be used to cut a variety of materials, including metal, plastic, and leather. Despite their versatility, these machines require a certain level of maintenance to ensure they function properly.

Maintenance requirements for a hydraulic cutting machine include daily cleaning, regular lubrication, and inspections. It is important to keep the machine clean to avoid clogging filters and causing electrical failures. It is also important to inspect the machine regularly for damage or serious wear and tear.

Regular lubrication of all moving parts is necessary for proper machine performance. It is recommended to use a large brand anti-wear hydraulic oil. In addition, it is important to keep the oil tank and filter clean and replace the oil as needed. This will help prevent mechanical failures and prolong the lifespan of the machine.

Cost

The cost of a hydraulic cutting machine can vary depending on its features and capabilities. However, it is important to consider the quality and durability of the machine when making a purchase, as it will save you money in the long run. It is also important to understand the maintenance needs of a hydraulic cutting machine, including proper lubrication and cleaning.

A hydraulic cutting machine is a versatile tool that can be used in a variety of industries. Its ability to cut metal sheets and other materials with precision ensures a high-quality product. It can also be used to cut and shape materials, such as foam and textiles.

When selecting a hydraulic cutting machine, there are several factors to consider, such as the manufacturerãs reputation, production capacity, and safety features. It is also important to check the machineãs certification and after-sales service. These factors will help you select the best manufacturer for your business needs.